<< Back to JFC Home |

Introduction: JFC Offers a unique concept to reality service for clients that require design,developed and manufacture of medium to large scale hollow plastic parts. With over 21 experience in the rotational moulding sector utilizing leading edge technology JFC are uniquely positioned to offer the highest quality products and services. |

| 4 Stages from Concept to Reality

|

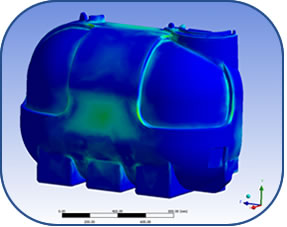

| 1. Product Design The product design process starts with the “product design specification” which sets out the aims and objectives of the product design. Once this is finalised a number of concepts will be developed using ProEngineer ,3D CAD software to meet the product design specification. The concepts are then reviewed in 3D and a final design will be agreed and developed into a detailed design. The detailed design then undergoes structural finite element analysis (FEA) where required which will identify any areas that need redesigning to meet the structural requirements. The final design then goes through the Design Review process before final product drawings are developed for sign off. |

|

|

|

||||

Mainly used for geometrically complex parts and parts that require specific surface textures and finishes.

The most widely used method of mould manufacture in rotational moulding. Used for both small and large parts with varying degrees of complexity.

JFC have a broad range mould building capabilities in house including - sheet metal moulds, CNC machined moulds and a combination of the two. The moulds are manufacturer in a purpose built workshop using state of the art equipment and machines. |

|

|||

The next stage is to produce production samples from the completed mould. During this stage the processing parameters are set and honed to produce a quality part. |

|